Prof. Dr.-Ing. Sabine Flamme

Dipl.-Ing. Julia Geiping

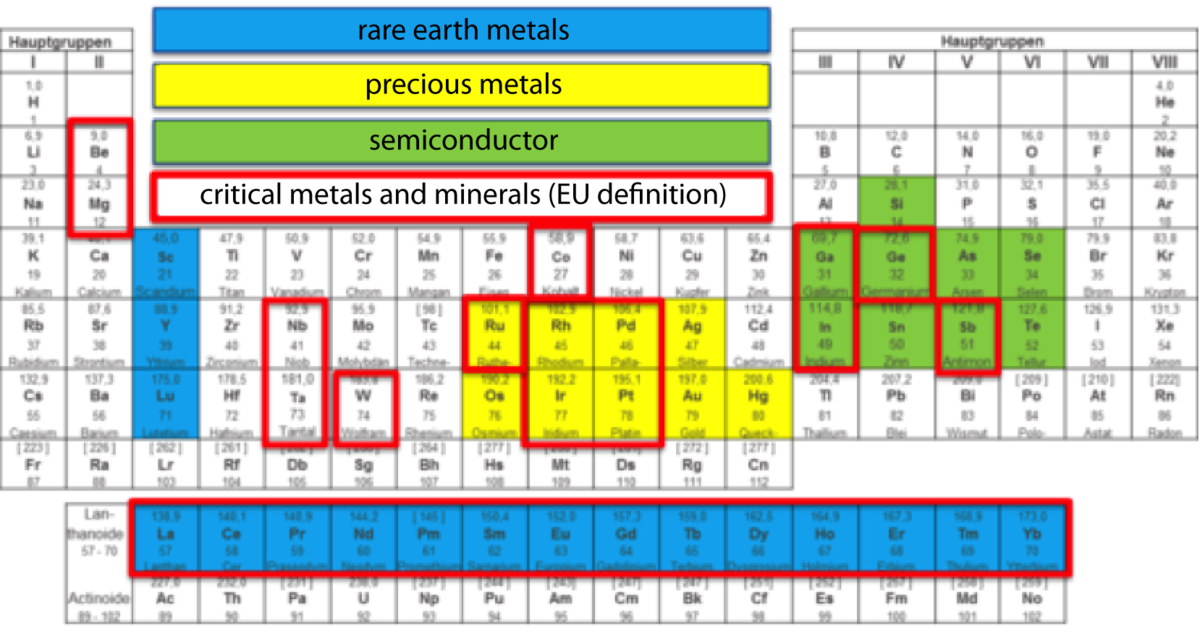

Many advanced technologies such as electromobility or solar energy are dependent on indium, gallium, antimony and rare earth metals. Although, as a location for industry, Germany is dependent on closing the materials cycle and utilising the products of recycling due to its geographical scarcity of raw materials, the proportion of recycling is completely inadequate. Complex recovery systems, high levels of export of used products and the absence of suitable recycling structures are challenges. Furthermore, the "electrical and electronic devices (EED)" material flow is highly complex and heterogeneous. It includes mobile telephones, coffee machines and electric toothbrushes, which makes device-specific processing difficult. In addition, the functionality of IT devices continuously increases and the innovation duration and serviceable life become shorter and shorter.

The enrichment of relevant trace metals can be achieved by the optimum coupling of all the players along the recycling chain. The experts see distinct potentials, not only in improving the recovery situation but, above all, in an adapted crushing and sorting technique such as selective fine comminution using the centrifugal mills which are used in the processing of cables. The objective of this process is to pelletise the litz wire material in order then to separate the lightweight materials from the pelletised material by density separation. Other options are incorporating additional screening and inspection steps are the use of sensor technology.

The intention is to investigate the impact of different mechanical processing steps with the aid of process-orientated material flow analyses in pilot plant and commercial trials over the course of the doctoral studies. For this purpose, a variety of approaches will be jointly investigated with aggregate manufacturers in order to achieve, depending on the input material, a maximum recoverable material flow reclamation rate. The main objective at this point in the value-added chain is to enrich the material flows generated for the last step, the thermal, chemical or metallurgical processes, or to deplete of impurities such that as clean a recovery of metals as possible is facilitated.